Safety and Protection

General Safety Precautions

All components must be operated inside a laboratory fume extraction cupboard.

When using medium pressure UV and Daylight lamps cooling must be provided by passing water or similar liquid, at a minimum flow of 2 litres per minute through the double wall of the immersion well, to prevent the lamp from over heating. It is strongly recommended that an automatic means, such as the Photochemical Reactors Flow monitor (Model PRC2), of shutting the lamp off in the event the water flow is restricted.

When the lamp is due to be operated the reactor should be screened with the reflective metal foil supplied, this is wrapped around the flask and other exposed parts, the foil will reflect light back into the reactant and also, avoid distraction to personnel present in the vicinity.

When a UV lamp is being used measures must be taken to prevent the operators being exposed to UV radiation. As well as the foil covering of the flask the reactor should be operated either behind an appropriate shield (S125 or 400S) or preferably in a Photochemical Reactor Two Part Shield and the operators provided with UV protection googles.

Lamps should be handled carefully by holding the brown insulation frame support at the top, and lowered gently into the immersion well.

Do not attempt to start the lamp when it is hot, allow the lamp to cool down, this can take up to 30 minutes with the cooling water flowing through the immersion well.

heavy duty reflective metal foil

UV Protection

Photochemical Reactors Ltd offer a number of ways to protect the operator from the dangers of UV radiation. These include heavy duty metal foil to wrap around the areas that emit UV, also screens that block UV radiation, goggles and two part enclosures should ensure that all dangers are eliminated, at the same time giving the flexibility to carry out experiments.

Model S125 Screen

Adjustable metal screen to shield the operator from UV radiation from the lamp (attached to the support stand)for use with the Small Immersion Well Reactor SQ125. Note the support stand shown is for illustrative purposes and is not included with the shield. Support stands maybe supplied separately by Photochemical Reactors (See price list).

Model S400 Screen

Adjustable metal screen to shield the operator from UV radiation from the lamp (attached to the support stand)for use with the Small Immersion Well Reactor SQ400. Note the support stand shown is for illustrative purposes and is not included with the shield.Support stands maybe supplied separately by Photochemical Reactors (See price list).

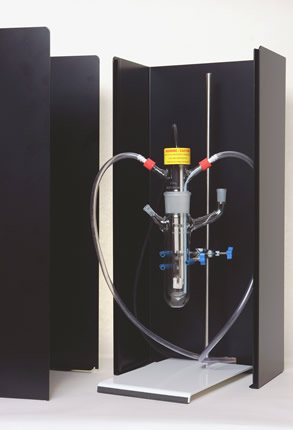

Model TPE/125/400 Two Part Screen

The Two Part Screen is opened and closed with a handle at the front. The power supply is operated outside with the lamp cable and water cooling tubing passing into the enclosure through gaps at the bottom. The Two Part Screen is recommended for use with both the Small Immersion Well Reactor SQ125 and the Large Immersion Well Reactor SQ400 and provides all round protection and easier access to the reactor than the screens.

Depth (closed) 48cm, Width 41cm, Height 70cm. Weight (back) 6 kilos, (front) 3 kilos. Note support stand and reactor shown is for illustrative purposes and is not included with the shield.Support stands SS/RQ125 AND SS/RQ400 maybe supplied separately by Photochemical Reactors (See price list).

Model UVPG UV Blocking Goggles

The UV Goggles block ultraviolet radiation while providing optimum contrast in viewing and lessened eye fatigue. The UVC-503 Goggles are lightweight and fit comfortably on the face, even over prescription glasses and have air vents that are located on each side to allow air flow while blocking the ultraviolet radiation.

Important: The goggles are designed for eye protection from lamps emitting wavelengths of 254nm to 365nm (nanometers). These UV Blocking Goggles also reduce longwave ultraviolet “blue haze” for optimum viewing.

Caution: Although the Goggles are intended to protect the eyes, care must be taken to protect other parts of the body from skin burn associated with shortwave UV wavelengths. Avoid shining any ultraviolet lamp on reflective surfaces. Wear protective clothing and skin cream

Flow Monitor

Introduction

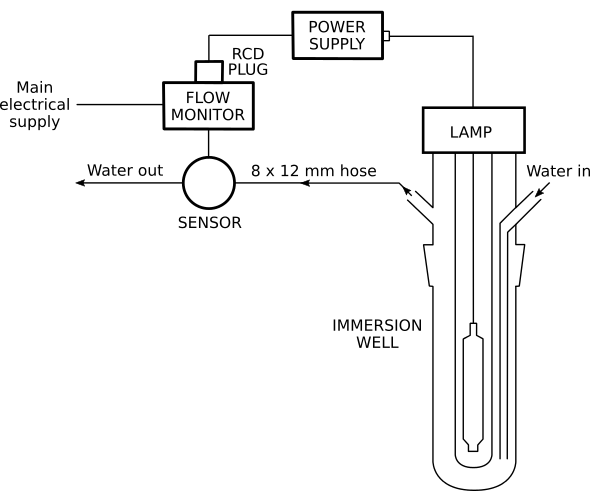

This flow monitor was developed as a safety device to be used with photochemical immersion well components, lamps, power supplies and immersion wells (cooling jackets).

When the lamps are operating they are producing ultraviolet or visible radiation, and also radiated heat – this heat must be removed to allow the lamp to operate at the correct temperature, and for the safety of the operators and their environment. The heat is removed by passing water, at flow rate of at least 2 litres per minute, through the immersion well that contains the lamp.

It is strongly recommended that the lamp power supply is connected to the flow monitor, and the flow monitor sensor is connected to the exit hose from the immersion well. If the cooling water stops flowing, an alarm sounds and the lamp automatically stops operating.

General operation

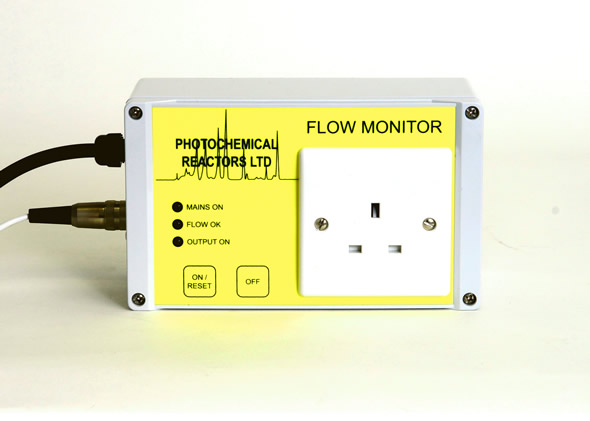

When the flow monitor is first powered on the 'Mains On' LED will light and the 13A output socket will be off.

When the measured flow exceeds approximately 0.4 litres per minute the 'Flow OK' LED will light.

If the measured flow falls below approximately 0.3 litres per minute the 'Flow OK' LED will extinguish.

When the 'Flow OK' LED is on, the output can be turned on by pressing the 'On / Reset' button.

When the output is on, if the flow fails, the 'Flow OK' LED will go out and the alarm will sound. If the flow is restored within 10 seconds, the alarm will stop and the output will remain on. If after 10 seconds the flow is not restored, the output will be turned off and the alarm will continue to sound until the 'On / Reset' button is pressed.

The output can always be turned off by pressing the 'Off' button.

LED operation

- Mains On – mains power to the unit is on

- Flow OK – there is sufficient flow detected

- Output On – the 13A outlet on the front of the unit is on

Pushbutton operation

- On / Reset – turns the output on if there is sufficient flow detected or resets the alarm

- Off – turns off the output

Note that the sounder beeps when a button is pressed.